Making Extremely Wear-Resistant Plastic Gears with 3D Printing

Por um escritor misterioso

Descrição

Using SLS with iglidur® high-performance polymers developed by igus allows manufacturers to make customized plastic gears.

Guide to SLS Post-Processing Techniques: Media Blasting, Smoothing, Coating, Coloring, and More

3D printed wear-resistant plastic gears for prototyping

The Use of Plastic Gears in Industries

5 Engineering Grade Plastics To Replace PLA - Fusion 3 Design

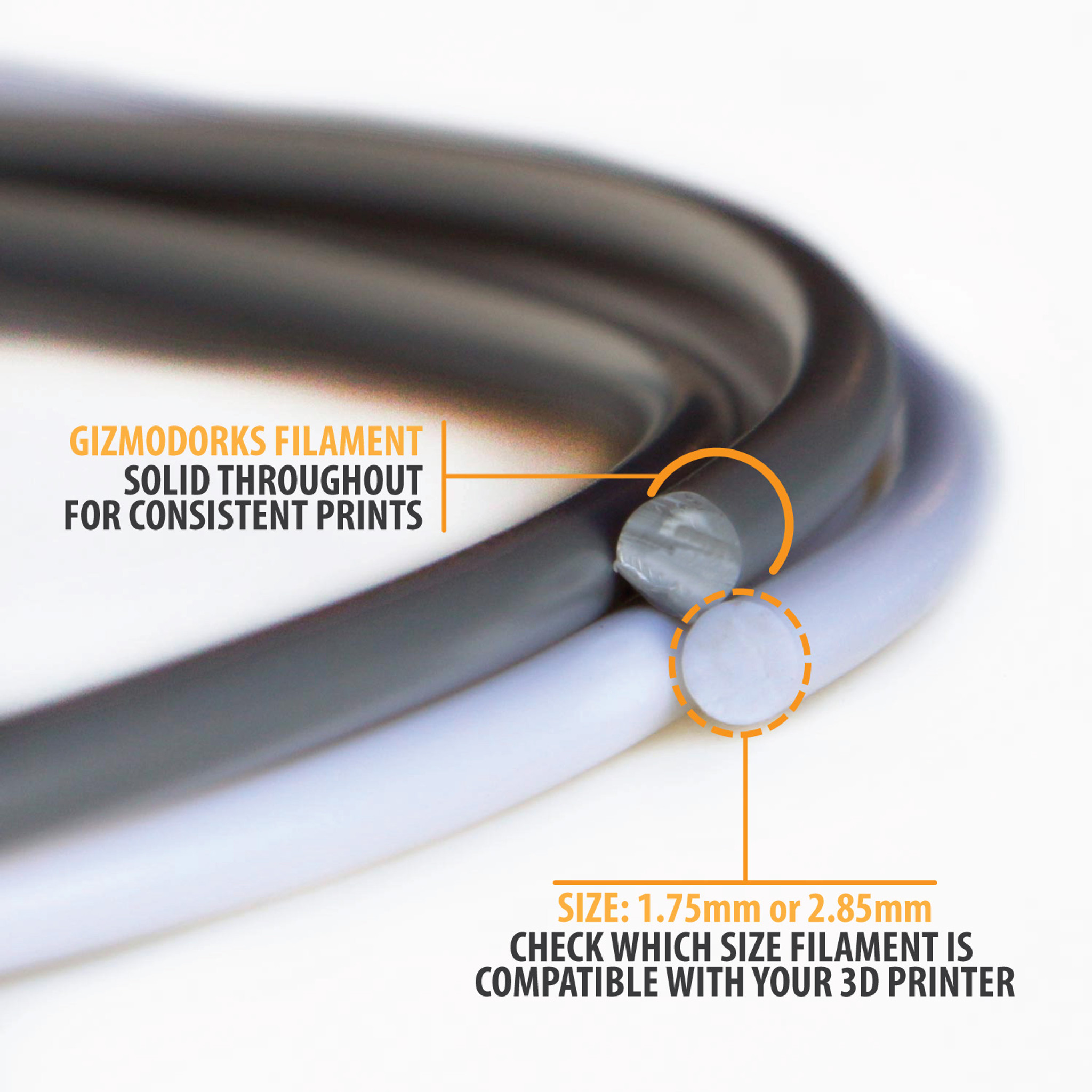

3D Printing Nylon Filament - Gizmo Dorks

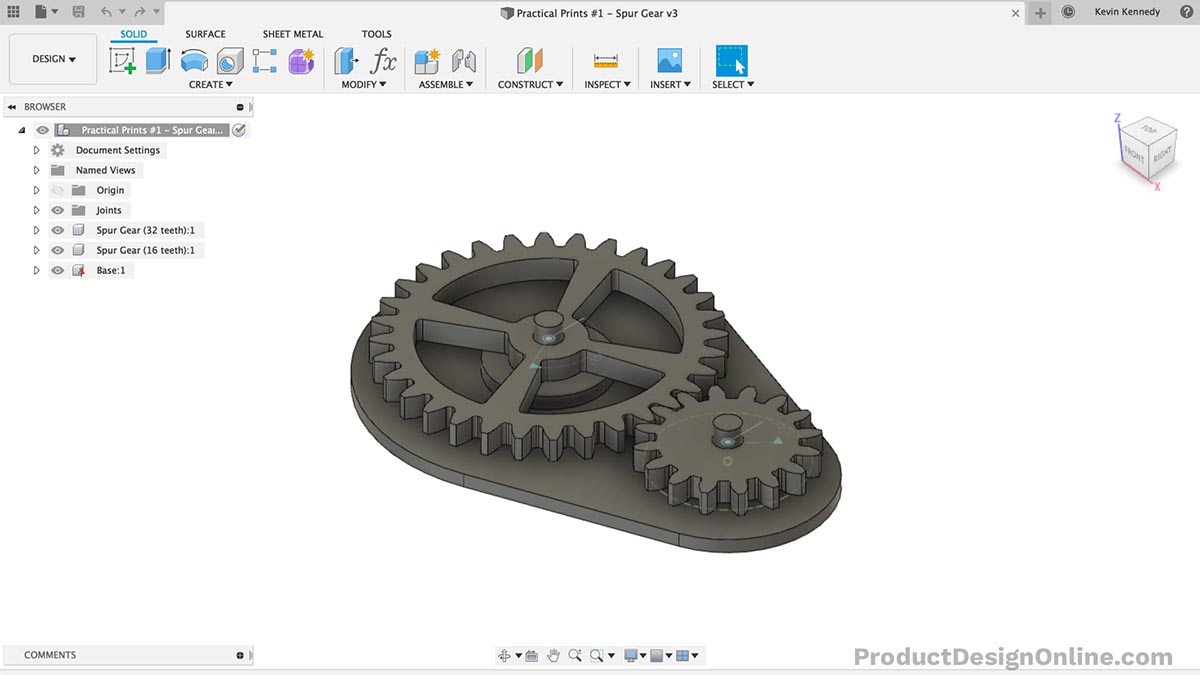

Create Custom 3D Printable Gears in Fusion 360

When 3D Printing Gears, It Pays To Use The Right Resin

What is the strongest 3D printing material? - UltiMaker

How to design for 3D printing - optimize your 3D models for print

Plastic Gears: Design, Materials, Types, Advantages, and Disadvantages

5 Engineering Grade Plastics To Replace PLA - Fusion 3 Design

de

por adulto (o preço varia de acordo com o tamanho do grupo)